The choice of more than 3000 domestic enterprises

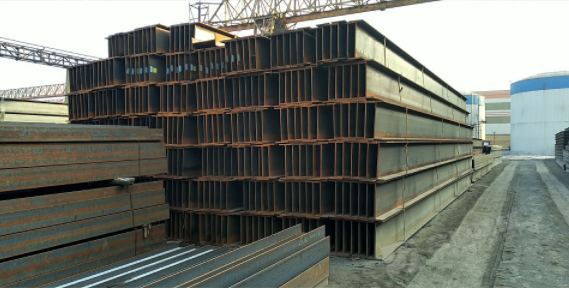

In the industrial manufacturing sector, H-beams are widely used in structures such as buildings, bridges, and towers due to their structural stability and load-bearing capacity. To ensure the surface quality of H-beams and extend their service life, surface cleaning is of utmost importance. This article explores how to enhance the cleaning effect of H-beams by selecting appropriate steel shots.

Impact of Steel Shot Hardness on H-Beam Cleaning Effectiveness

The hardness of steel shots is one of the key factors influencing the cleaning effectiveness of H-beams. According to data, steel shots typically have a hardness ranging from HRC40 to HRC50. For common steel welded parts, castings, and the like, steel shots within this hardness range can effectively perform surface cleaning. Harder steel shots can more forcefully impact the workpiece surface, thereby more effectively removing impurities such as rust, scale, and old coatings. However, excessively hard steel shots may cause excessive damage to the H-beam surface, especially for softer materials or thin-walled workpieces. Therefore, selecting steel shots with moderate hardness is crucial for H-beam cleaning.

(S780)

Impact of Steel Shot Particle Size on H-Beam Cleaning Effectiveness

The particle size of steel shots also affects the cleaning effectiveness of H-beams. Larger steel shots exert greater impact on the surface, making them suitable for removing thick coatings, while smaller steel shots provide finer processing, suitable for the fine processing of thinner materials. For H-beam cleaning, the appropriate steel shot particle size should be selected based on the specific surface condition and cleaning requirements. For example, for H-beams with severe surface rust or the need to remove thick oxide layers, larger particle size steel shots may be required; whereas for H-beams with smoother surfaces that only require the removal of thin layers of rust or coatings, smaller particle size steel shots can be chosen.

Rebound and Coverage of Steel Shots

The rebound of steel shots is equally important for the cleaning effectiveness of H-beams. Steel shots with good rebound can reach every part of the cleaning chamber, reducing processing time. Additionally, the coverage of steel shots also affects the cleaning effectiveness. Appropriately increasing the shot blasting intensity and coverage helps to enhance the shot peening effect. However, excessive coverage can also lead to an increase in surface roughness, so the coverage of shot blasting needs to be adjusted according to the specific requirements of the H-beams.

By comprehensively considering the hardness, particle size, rebound, and coverage of steel shots, efficient and economical surface treatment of H-beams can be ensured, thereby improving the quality and service life of H-beams. The correct selection of steel shots, combined with appropriate shot blasting processes, will provide the best surface cleaning effect for H-beams.

Your Most Thoughtful Expert in Anti-corrosion and Rust Removal!

Consultation Hotline: 400-038-8928

Telephone: 027-84841595

Steel Shot Sister Hotline: 13016427928

Official Website:www.malgw.com

Disclaimer: horsepower steel sand part of the article information from the network reprint is for the purpose of transmitting more information, does not mean to agree with its views or confirm the authenticity of its content. If the article involves copyright and other issues, please contact our online customer service immediately, and we will deal with them as soon as possible to ensure your rights and interests.

Without permission, it is forbidden to collect and mirror all the graphic content of the website in any form, otherwise, you will be responsible for the consequences!

Last article:The Effect of Different Grain Sizes of Steel Shot on Polishing Performance

Next article:The Influence of Hardness and Density on Steel Shot

China's iron and steel industry is suffering serious losses. As it enters the "cold winter" of the industry, more and more iron and steel enterprises are leveraging the Internet economy to promote the operation coordination and overall optimization of the

2020-01-16- How are the hardness grades of steel shots classified?

- Cost analysis using different types of steel shots

- Changshu Changfeng Steel Pipe Co., Ltd. won the title of Made in China Champion Enterprise

- Hongxin steel shot takes you to know shot peening strengthening technology. If you understand it, you will become an expert

- The Effect of Different Grain Sizes of Steel Shot on Polishing Performance

Contacts: Manager Chen

Tel: 010-82388888

Mobile phone: 13810471933

Company address:No.126-3, building 1, shangfengyuan, Baijiatuan, Haidian District, Beijing